As we’ve been observing recession around the world, caused by the pandemic of Covid, and the war in Ukraine, we may not be aware of why the prices and the inflation rate are so high. In the aftermath of the stock market collapse, transportation costs have increased, labour shortages have occurred, demand has fluctuated, and critical goods have become scarce. How are the supply chains and logistics affected by changes in the Stock Market?

Table of Contents

The supply chain shift

The reduction of spending is one of the most natural consequences of a recession. Lots of us limit our shopping to necessities, such as groceries or toiletries, refraining from buying clothes or electronics.

As a result, companies may need to modify their product portfolios and start manufacturing the least expensive items. The companies manufacturing everyday products won’t probably see a big difference. The manufacturers of more exclusive goods will experience a reduction. The supply chain will be deeply affected, with the need of adapting to new ordering, inventory and production strategies.

Companies experiencing the change in demand, should quickly adapt and shift the production to the goods driving the most revenue. In case of a shortage of necessary materials, the prices of the product should grow up.

The comeback of regional logistics

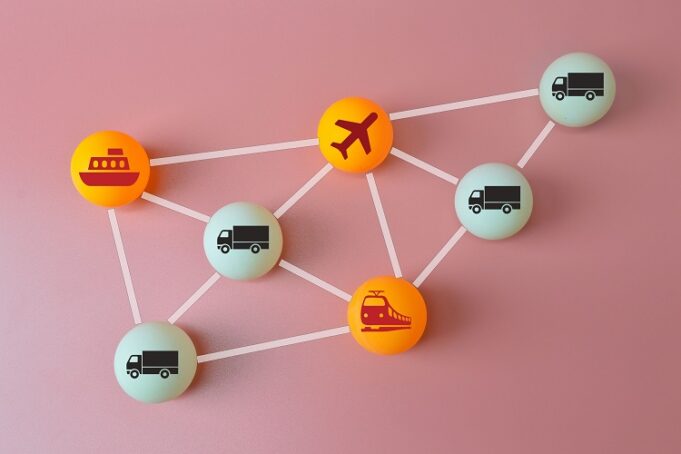

The stock market decline and the changes in the supply chain will sooner or later cause logistics companies to come back to regional transportation. We are coming to the end of the golden age of international freight transportation, and it is time to return to good old regional freight transportation.

The logistics industry is also facing another problem, caused by unskilled labour and the ageing workforce. That’s a big chance for those who would like to try a new career. There is a need for HGV drivers, that’s why it’s the best moment for HGV training.

Cash flow decreased

Due to the serious problems with the availability of materials and different products, lots of companies went for bulk orders, and are now left with excess inventory. The consumers’ lower demand and the excess inventory will pause companies from ordering new goods from their suppliers.

It’s challenging to find a good solution in the situation, as the companies with bulk orders will sooner or later have to offer discounts on their products, which in a time of recession may be an additional decrease in income. On the other hand, the suppliers without orders from their regular customers will lose trust, and as a result, receive shipments in the last order.

Fewer orders from suppliers mean trouble for logistics companies too. Instead of regular transportation of orders, they pause and need to find other clients who will need their services.